What is High-Visibility Safety Apparel?

High-visibility safety apparel is clothing (e.g., vests, bibs, or coveralls) that workers can wear to improve how well other people "see" them (their visibility). Most often, high-visibility clothing is worn to alert drivers and other vehicle operators of a worker's presence, especially in low light, bad weather and dark conditions. High-visibility headwear can also be worn to increase the visibility of the wearer in situations where part or all of the wearer's body could be obscured (e.g., leaves/trees, traffic barriers, construction materials, etc.)

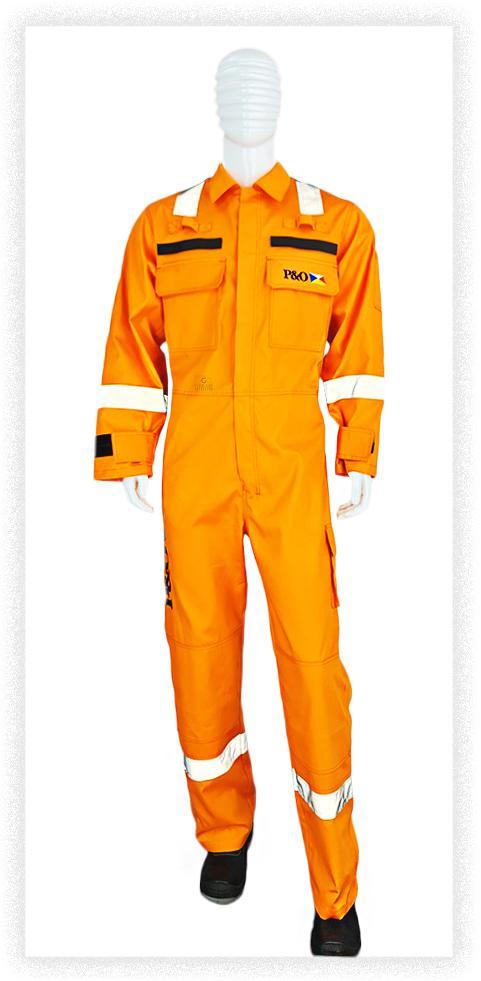

Design requirements for high-visibility safety clothing are generally found in variety of standards dedicated to work wear requirements. Considering diversity of businesses from all over the world acting in Kazakhstan High-Visibility Safety Apparel normally is chosen using a more strict regulation that companies set above legal requirements in the country. SGK complies with these design requirements and manufactures garments according to client technical specifications.

Why do you need High-Visibility Safety Apparel?

Hi-Vis garments are needed if your personnel works when there is low light and poor visibility, especially when moving vehicles (cars, trucks or other machinery traveling under their own power, such as , forklifts, backhoes, etc) are normal during operations at work site. High-visibility items allow the drivers of those vehicles seeing personnel from farther away so that they can respond accordingly, which increases safety at work. The human eye responds best to large, contrasting, bright or moving objects. Worker visibility is enhanced by high color contrast between clothing and the work environment against which it is seen.

When do you need High Visibility Safety Apparel?

Before selecting high-visibility safety apparel, confirm the legislative requirements for the area of your operations and company HSE standards. For example, certain jobs may require specific apparel.

Typical occupational health and safety standards recommend that a proper hazard assessment is carried out on each job site to evaluate the workplace or work site for known or potential hazards a worker may encounter while performing a job or task. This assessment helps determine the risk to workers of being hit by moving vehicles and the environmental conditions under which work is performed. This is when Hi Vis garments can be introduced as additional safety measure.

When doing a hazard assessment be sure to consider Hi-Vis garments in the following conditions by the nature of operations:

- Workers and mobile equipment need to interact (e.g., construction sites, warehouses, drilling floor)

- Workers control traffic and interact with public (Police, Law Enforcement officers, Marshals, Volunteers at public meetings and others)

- Workers need to be visually identifiable from others in the area (Emergency Response Coordinators, Fire Wardens, Security officers, Paramedics, etc)

- Industry specifications and good practice

Work conditions, such as indoor or outdoor work, temperature, work rates, traffic flow, traffic volume, visibility, etc may also be factors driving towards introduction of Hi-Vis garments into operations to increase safety. The workplace environment and the background workers must be seen in (e.g., is the visual area behind the workers simple, complex, urban, rural, highway, filled with equipment, cluttered) allows picking correct main and dominating colors to create contrast unless typical fluorescent lemon is not suitable.

Workers' exposure to various traffic hazards including traffic speeds is a critical factor to consider. It becomes even more critical in conjunction with lighting conditions and how the natural light might be affected with changing weather. Factors that affect warning distances and times, such as the volume of traffic, the size of vehicles, their potential speeds, the ability to stop quickly, and surface conditions.

Other factors like permanent engineering controls and barriers, administrative behavioral training, potential distractions that may draw attention away from hazards, typical sightlines of mobile equipment and vehicle operators (especially when operating in reverse is a normal situation) play an important role to weigh all the Pros and Cons for choice of Hi-Vis apparel.

Be sure to comply with FR requirements in case of potential exposure to heat and flames.

What are the different classes of safety apparel?

Although this may differ slightly in various standards (normally the differences are in coverage area specifications to minimum areas requirements) they generally agree on the following classification:

- Class 1 provides the lowest recognized coverage and good visibility.

- Class 2 provides moderate body coverage and superior visibility.

- Class 3 provides the greatest body coverage and visibility under poor light conditions and at great distance.

SGK design and classification follows these rules and it is possible to segregate apparel in shop with the filters applied on the left-hand menu when searching garments that fit your requirements.

The design team utilizes variety of materials to set high visibility and retroreflective (i.e., the effectiveness of material in returning light to its source) performance of garments we manufacture. The colors and luminosity of main materials comprising the body of garments and how much of the body is covered by the high-visibility components like light reflecting stripes, in-seam hems, or heat pressed decorating elements are considered in design to fit Client budget and requirements versus material and manufacturing costs.

Hi-Vis Apparel by Class Show Cases

The following is our recommendation that you may consider during your risk assessment, but it will always be your particular industrial conditions and your HSE regulations to choose how you apply known regulations on High-Visibility Safety apparel and how you leverage possibility to use flexible materials garments maintaining your personnel's safety.

Low Risk

Class 2, Class 1 apparel may be worn under certain conditions at low risk that can be described as:

- Workers performing activities that permit their full and undivided attention to approaching traffic.

- When there is ample separation between workers on foot and traffic or other mobile equipment.

- When work backgrounds are not complex, allowing for optimal visibility.

- When vehicles do not exceed 40 km/h.

- When workers are doing tasks that divert their attention from approaching traffic.

Options with non-high-visibility material, but with high-visibility or retroreflective stripes/bands are possible.

Apparel Examples for Low Risk

Medium Risk

Class 2 or 3 based on certain conditions may be used at medium risk in the following circumstances:

- When vehicles or equipment are moving between 40-80 km/h.

- Workers who require greater visibility under inclement weather conditions or low light.

- When work backgrounds are complex.

- When workers are performing tasks that divert attention from approaching vehicle traffic.

- When work activities are in closer proximity to vehicles (in or near flowing vehicle traffic).

Options with combined performance of retroreflective stripes/bands (silver or white) with bright yellow or bright orange fabric of the garment's main body. Combination of contrast colors and usage of fluorescent/luminous materials is an asset for complex landscapes.

Garments for Medium Risk

High Risk

Class 2 for daytime, Class 3 for low-light conditions should be used at high risk in the circumstances that may include:

- Vehicle speeds exceeding 80 km/h.

- Workers on foot and vehicle operators have high task loads that clearly place the worker in danger.

- When the wearer must be conspicuous through the full range of body motions at a minimum of 390 m.

- Work activities taking place in low light or at nighttime.

- When weather conditions are prominent for bad visibility (fog, mist, heavy rain).

Options with combined performance of retroreflective stripes/bands (silver or white) with bright yellow or bright orange fabric of the garment's main body. Combination of contrast colors and usage of fluorescent/luminous materials is an asset for complex landscapes.

Garments for High RiskWhat Hi-Vis Apparel should look like?

Market has lots to offer. Our shop has a wide variety. It may all be confusing. Here is a short guide

Coverage/Visibility

Employers should select the color and stripe combination that provides the preferred contrast, visual indication of movement, and direction of travel to achieve the highest impact from introducing/maintaining high visibility on their sites.

- Bright colors of main fabric are more visible than dull ones. Depending on the landscape that might be bright too it is some times a good idea to combine bright and dark colors. Either case coverage all around the body is always a good idea as it provides better visibility from all directions.

- Contrast color stripes around legs and arms give clues for motion of the person wearing hi-vis garment.

- Bright fluorescent/luminous materials generally improve visibility, but they do not provide retroreflective properties as special bands and stripes do.

Proper Fit

For safety and best performance, garments should fit the person. Proper fit includes wearing the garments as intended and considering any additional clothing worn underneath the high-visibility apparel. The garments should sit correctly on the body and stay in place during work.

The apparel should be comfortable to wear. Any seams and materials should not cause discomfort or irritation to the wearer (e.g., no sharp edges or projections, no rough material). The apparel should also be of appropriate weight, and provide adequate stretch and flexibility.

Garments should be selected and worn so that no other clothing or equipment covers the high-visibility materials (e.g., backpacks, glove gauntlets, equipment belts, and high-cut boots).

Brightness

Daylight - Bright colors are more visible than dull colors under daylight conditions (e.g. fluorescent materials are suitable for daylight).

Low light conditions - Fluorescent colors are more effective than bright colors under low light (e.g. dawn and dusk). Under these conditions, reflective materials are also suggested.

Dark conditions - Retroreflective material provides greater visibility and are preferred over bright colors alone under low light conditions. As fluorescent materials require natural light, they are ineffective at night or when no natural light is present.

Stay Updated!

Subscribe to our newsletter to receive more interesting content directly to your inbox.

Don’t miss out on the latest updates, insights, and exclusive offers!

Care/Maintenance

Keep high-visibility apparel clean and well-maintained. Contaminated or dirty retroreflective materials provide lower visibility.

Replace garments that show signs of wear and tear, soiling, or contamination as it will no longer be able to provide acceptable levels of visibility.

Purchasers of high-visibility apparel should get proof that the materials used, and the design of the garment meet the requirements of corresponding standard. Generally, the garment’s tag will state if it meets the requirements. When dealing with SGK bear in mind that at no conditions our employees will not rate and tag garments to a higher visibility class than stated in applicable standards or specifications.

High Visibility Apparel